Wood drying machine

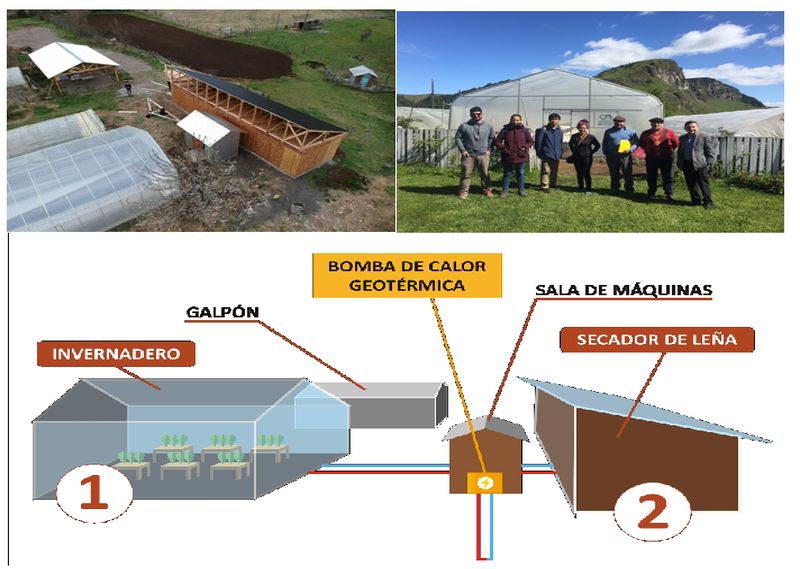

The Centro de Energía (CE) together with the Centro de Excelencia en Geotermia de Los Andes (CEGA), both from the Faculty of Physical and Mathematical Sciences of the Universidad de Chile, implemented this project of direct use of geothermal energy to improve the living conditions of a community in a sustainable way and establishing a resilient socio-technical system. The project is located in the city of Coyhaique, a town located in the extreme south of the country, which has a strong dependence on imports of agricultural products due to its adverse climatic conditions, and has one of the highest per capita consumption of firewood in the country, which translates into high levels of particulate matter pollution. According to the Third State of the Environment Report (Ministry of the Environment, 2016) Coyhaique is the city with the highest concentration of particulate matter 2.5 measured throughout the country, and according to the WHO, in 2016 it was the most polluted city in the entire American continent.

The project is developed thanks to funding from the Ten-Year Framework of Programs on Sustainable Consumption and Production (10YFP) (www.unep.org/10YFP/lifestyles) and the Institute for Global Environmental Strategies (IGES) of Japan (https://www.iges.or.jp/en/scp/index.html ). In addition, the Stockholm Environment Institute (https://www.sei-international.org ) provides the technical secretariat for the project. UNEP acts as the Secretariat of the 10YFP and administers its Trust Fund.

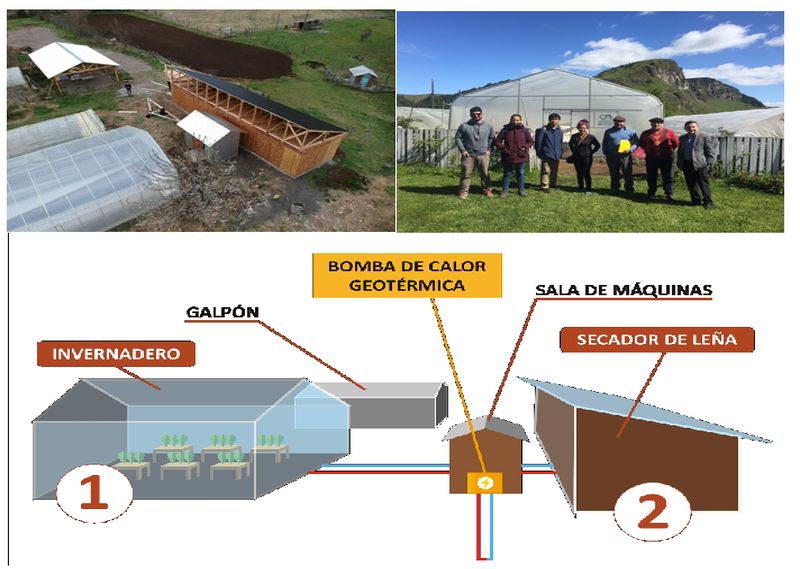

The project consists of 3 modules or areas that are developed independently: The firewood dryer consists of a container where hot dry air is injected which causes the wood inside to lose water, and then the moist air is extracted. The dryer occupies an area of approximately 64 m2, and has a capacity of 48 m3 of firewood, which translates into 30 m3 of stacked firewood. In conjunction with the geothermal heating, the dryer has a translucent roof that allows the incoming air to be preheated by solar input alone. Vegetable greenhouse The greenhouse has a surface area of 210 m2, where hydroponic vegetables are grown, consisting of 2,000 heads of lettuce. Hydroponics consists of the NFT (Nutrient Film Technique) system, in which a film of water containing the necessary nutrients is circulated through the plant roots. This water reaches a pond where it is heated with geothermal energy to maintain a temperature of 20 °C. The greenhouse also has fan coils fed by this system to maintain the temperature inside the greenhouse. The geothermal heat system corresponds to the heat source that feeds the dryer and the greenhouse. Like a traditional air conditioning system, it uses a compressor to extract heat from a cold source and injects it into a hot zone. The particularity of the geothermal pump is that it extracts heat from the subsoil, which has an almost constant temperature throughout the year, which allows it to be more efficient if this heat were extracted from the cold ambient air. Therefore, water is extracted directly from the groundwater to pass through the heat pump and then be re-injected into the water table.

More information at: www.energiasosteniblechile.cl

Wood drying machine

The Centro de Energía (CE) together with the Centro de Excelencia en Geotermia de Los Andes (CEGA), both from the Faculty of Physical and Mathematical Sciences of the Universidad de Chile, implemented this project of direct use of geothermal energy to improve the living conditions of a community in a sustainable way and establishing a resilient socio-technical system. The project is located in the city of Coyhaique, a town located in the extreme south of the country, which has a strong dependence on imports of agricultural products due to its adverse climatic conditions, and has one of the highest per capita consumption of firewood in the country, which translates into high levels of particulate matter pollution. According to the Third State of the Environment Report (Ministry of the Environment, 2016) Coyhaique is the city with the highest concentration of particulate matter 2.5 measured throughout the country, and according to the WHO, in 2016 it was the most polluted city in the entire American continent.

The project is developed thanks to funding from the Ten-Year Framework of Programs on Sustainable Consumption and Production (10YFP) (www.unep.org/10YFP/lifestyles) and the Institute for Global Environmental Strategies (IGES) of Japan (https://www.iges.or.jp/en/scp/index.html ). In addition, the Stockholm Environment Institute (https://www.sei-international.org ) provides the technical secretariat for the project. UNEP acts as the Secretariat of the 10YFP and administers its Trust Fund.

The project consists of 3 modules or areas that are developed independently: The firewood dryer consists of a container where hot dry air is injected which causes the wood inside to lose water, and then the moist air is extracted. The dryer occupies an area of approximately 64 m2, and has a capacity of 48 m3 of firewood, which translates into 30 m3 of stacked firewood. In conjunction with the geothermal heating, the dryer has a translucent roof that allows the incoming air to be preheated by solar input alone. Vegetable greenhouse The greenhouse has a surface area of 210 m2, where hydroponic vegetables are grown, consisting of 2,000 heads of lettuce. Hydroponics consists of the NFT (Nutrient Film Technique) system, in which a film of water containing the necessary nutrients is circulated through the plant roots. This water reaches a pond where it is heated with geothermal energy to maintain a temperature of 20 °C. The greenhouse also has fan coils fed by this system to maintain the temperature inside the greenhouse. The geothermal heat system corresponds to the heat source that feeds the dryer and the greenhouse. Like a traditional air conditioning system, it uses a compressor to extract heat from a cold source and injects it into a hot zone. The particularity of the geothermal pump is that it extracts heat from the subsoil, which has an almost constant temperature throughout the year, which allows it to be more efficient if this heat were extracted from the cold ambient air. Therefore, water is extracted directly from the groundwater to pass through the heat pump and then be re-injected into the water table.

More information at: www.energiasosteniblechile.cl